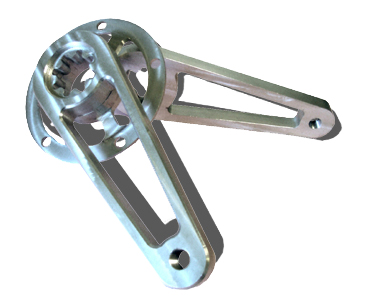

BOBset Bicycle Crankset

The Challenge

Bicycle cranksets are often an unglamorous component, positioned near the dirt and grime of the road and trail. Yet they are also one of the most crucial, as every watt of power generated by the rider must be carried by the crankset.

Traditional cranksets are forged in a solid piece, and suffer from a compromised shape as a result. Too thin to resist flex, and with an inefficient mount to the bottom bracket, power is lost with each pedal stroke. As a manufacturing design project, this was an excellent opportunity to try a new approach. The cranks had to be stiffer and stronger than traditional cranks, at the same weight. They also should be easier to mount and maintain.

The Process

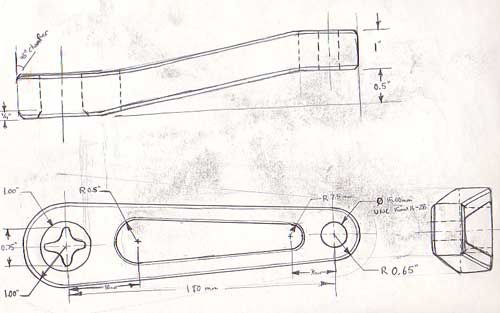

Existing cranksets all had a common design with a thin, solid arm. Stress-strain analysis found that a modified I-beam shape would be stiffer and stronger for the same weight. A series of sketches and foam prototypes gave users the opportunity to see design possibilities on their own bicycles.

Research on possible mounting shapes led to a smooth sine-wave-like curved mount, which gave both increased surface area and stiffness as well as simplifying the mounting process.

CAD drawings were made in SolidWorks and Vellum and translated to CNC mills to produce the final foam and aluminum prototypes.

The Solution

The I-beam formation lends stiffness while allowing for material to be removed from the center portion. Similarly, the crankset uses a proprietary bottom bracket that is larger in diameter than normal, to add stiffness in the bottom bracket and the frame.

CNC-machined 7010 aluminum alloy, threaded for standard pedals and to accept standard road 130-mm bolt circle chainrings.

The Benefits

- Increased stiffness

- Easy mounting to the matched bottom bracket

- No weight penalty